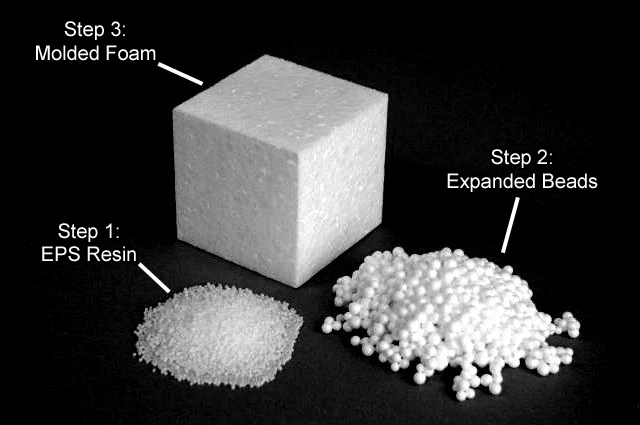

Expandable polystyrene is a product of styrene polymerization with the introduction of an expanding agent (gas) in the polymer composition. Expandable polystyrene is used in polymer processing into insulating panels and ready-to-use parts by expanding. The material has excellent heat-insulation and sound-proofing properties, high impact strength, vibration resistance, resistance to light, water repellency, dustproofness, and resistance to physical processing. The material is resistant to hydrolysis, oils, acids, solutions of alkalis and acids.

EPS is widely used in construction for production of panels for heat insulation

of walls and suspended ceilings (expanded plastic), as well as for production of thin-wall goods, fire-resistant industrial and food packaging.

Polystyrene is most commonly found in three forms. Rigid Polystyrene (PS), Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS).

Grades Bead size per-expansion Density Foam Multiply Foam Density Typical Application

F50 1.6-1.9 11 60-75 10-20 Insulation,big packing ,flame retardant

F100 1.2-1.6 13 47-65 14-22 Insulation,big packing ,flame retardant

F150 1.0-1.2 14 42-60 16-30 Insulation,big packing ,flame retardant

F250 0.73-1.0 15 35-55 20-35 Medium density,packing,flame retardant

F350 0.5-0.73 16 28-50 22-40 High density,special use,flame retardant

F200 0.9-1.3 13-20 packing product,insulation application,flame retardant

F300 0.7-0.9 14-20 Small parts and thin wall with good surface finish

F400 0.4-0.7 18 packing product,insulation application

R200 0.9-1.4 13-25 Food contact,insulation application

R300 0.7-0.9 13-25 Food contact,insulation application

R400 0.4-0.7 18 Food contact,insulation application

F101 1.2-1.8 12-20 packaging product, insulation application

F105 1.2-1.8 12-20 packaging product, insulation application

F201 0.9-1.3 13-20 packaging product, insulation application

F205 0.9-1.3 13-18 packaging product for food contact

F305 0.7-1 16-22 packaging product for food contact

F405 0.4-0.7 Above 20 cases and packaging product