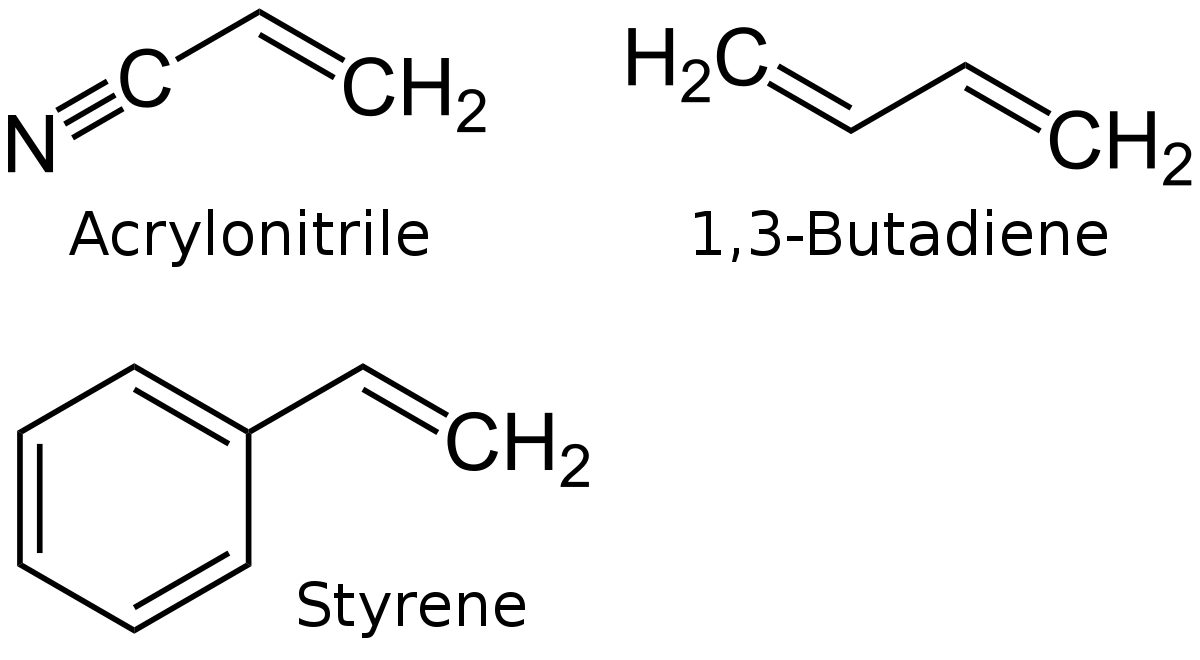

Acrylonitrile Butadiene Styrene, or ABS, is an opaque thermoplastic. It is an amorphous polymer comprised of three monomers, acrylonitrile, butadiene and styrene. ABS is most commonly polymerized through the emulsification process or the expert art of combining multiple products that don’t typically combine into a single product.

When the three monomers are combined, the acrylonitrile develops a polar attraction with the other two components, resulting in a tough and highly durable finished product. The different amount so f each monomer can be added to the process to further vary the finished product.

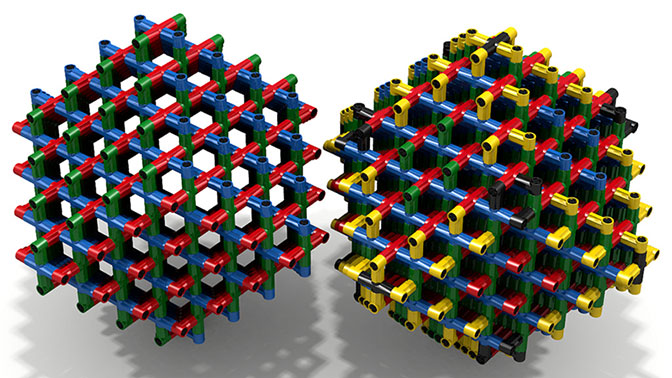

The versatility of ABS plastic properties contributes largely to its popularity across several industry sectors. From computer keyboard keys to LEGO, products made from ABS can be found all around the world in multiple domestic, commercial and specialist settings.

ABS material Properties

The acrylonitrile in ABS provides chemical and thermal stability, while the butadiene adds toughness and strength. The styrene gives the finished polymer a nice, glossy finish. ABS has a low melting point, which enables its easy use in the injection moulding process and 3D printing. It also has high tensile strength and is very resistant to physical impacts and chemical corrosion, which allow the finished plastic to withstand heavy use and adverse environmental conditions.

ABS can be easily moulded, sanded and shaped, while its glossy surface finish is highly compatible with a wider range of paints and glues. ABS plastics takes colour easily, allowing finished products to be dyed exact shades to meet precise project specifications.

ABS applications

As well as its uses in computer keyboard components and LEGO bricks, ABS is commonly used to make plastic face guards for wall sockets and protective housing for power tools. It is commonly used in the automotive field too, for items such as plastic alloys and decorative interior car parts. In the construction industry, ABS comes into its own in the manufacture or plastic tubing and corrugated plastic structures. It can be cut to size and comes in a wide range of colours and finishes. It also comes in handy in the manufacture of protective headgear such as hard hats and helmets. Other common uses for the ABS thermoplastic polymer include printers, vacuum cleaners, kitchen utensils, faxes, musical instruments (recorders and plastic clarinets, to name just two) and plastic toys.

Plastic items designed to live outside are often made from ABS as well since the versatile thermoplastic can stand up well to rain, storms and winds. However, to prolong its life outdoors, it must be adequately protected from UV rays and exposure to the more extreme weather conditions. Its relatively cheap production costs also enable it to be used cost-effectively for producing prototypes and plastic preview models.

More recently, ABS has been playing a key role in the rise and rise of 3D printing. ABS parts are readily available and can be easily moulded to create a desired form and effect. ABS can also be electroplated to enable even more options for its use. 3D printers are fast becoming a commonplace sight across manufacturers, educational institutes and even home-based printing businesses and other entrepreneurial initiatives.

Advantages

There are many ABS plastic advantages, from the reasonable production costs to its sturdy, aesthetically pleasing structure. Its ability to withstand being heated and cooled multiple times make it highly suitable for recycling. ABS is versatile in the range of colour and surface texture options that can be achieved and it can be manufactured to a very high-quality finish. It is lightweight and suitable for a vast range of applications. Finally, ABS has low heat and electricity conductivity that is especially helpful for products requiring electrical insulation protection. It also offers excellent impact resistance and can absorb shock effectively and reliably.

Grades MFI Color Application Typical Application

ABWH2 32 White Injection Home appliances and automotive components

ABBL2 32 Black Injection Home appliances and automotive components

ABRD2 32 Red Injection Home appliances and automotive components

ABGR2 32 Gray Injection Home appliances and automotive components

ABBR2 32 Brown Injection Home appliances and automotive components

ABWE2 7 Ice white Injection Home appliances and automotive components